A Cube Mould 150x150x150 (Non-ISI) is a specialized tool used in the construction and civil engineering industries for preparing concrete test specimens. These specimens are typically tested for compressive strength, which is a crucial parameter in assessing the quality and durability of concrete. Here’s a detailed description of its features and typical uses:

Key Features:

1. Material :

– Cast Iron or Mild Steel : Typically made from high-grade cast iron or mild steel, which provides the necessary strength and durability to withstand the pressures exerted during the compaction and curing of concrete.

– Non-ISI : Indicates that the mould does not conform to the standards set by the Bureau of Indian Standards (ISI). It might be used in non-critical applications or where adherence to ISI standards is not mandatory.

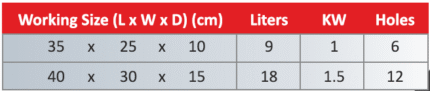

2. Dimensions :

– Internal Size : 150 mm x 150 mm x 150 mm (6 inches x 6 inches x 6 inches).

– External Size : Slightly larger due to the thickness of the walls.

3. Design :

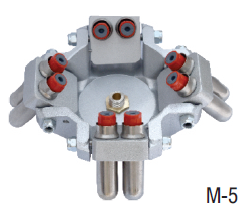

– Split Design : Often designed in two halves (split mould) to facilitate easy removal of the cured concrete cube without causing damage.

– Base Plate : Includes a detachable base plate on which the mould is assembled. The base plate provides a level surface for casting and compacting the concrete.

– Bolts and Wing Nuts : Equipped with bolts and wing nuts or screws to secure the two halves of the mould together during the casting process.

4. Usage :

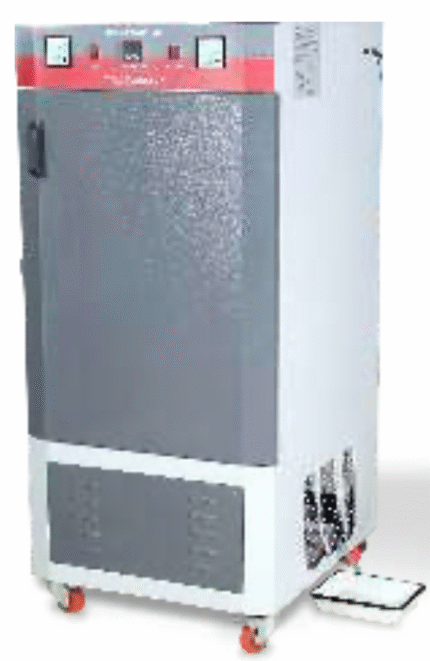

– Concrete Specimen Preparation : Used for casting concrete cubes to test the compressive strength of the concrete mix.

– Compaction : Concrete is poured into the mould in layers, and each layer is compacted either manually with a tamping rod or using a vibrating table to ensure there are no voids.

– Curing : After compaction, the concrete is allowed to set and cure, usually for 24 hours, before the cube is demoulded and further cured in water for a specified period (usually 7, 14, or 28 days) before testing.

5. Applications :

– Quality Control : Used in construction sites and laboratories to ensure that the concrete mix meets the required strength specifications.

– Research and Development : Employed in R&D to study the properties of different concrete mixes and additives.

– Education and Training : Utilized in educational institutions for teaching concrete testing methods and techniques.

6. Maintenance :

– Cleaning : Requires thorough cleaning after each use to remove any concrete residue and prevent rusting.

– Inspection : Regular inspection for any wear or damage to ensure the mould maintains its shape and integrity.

Advantages:

– Durability : Made from robust materials to withstand repeated use and the stresses of concrete compaction.

– Ease of Use : Split design with bolts or wing nuts facilitates easy assembly, disassembly, and removal of the cured concrete cube.

– Accuracy : Provides precise dimensions for preparing standard-sized concrete test specimens.

Limitations:

– Non-ISI : Being non-ISI, it may not meet specific regulatory or quality standards required for certain critical applications.

– Weight : Can be heavy and cumbersome to handle, especially in field conditions.

Reviews

There are no reviews yet.